We get emails from consumers and afficionados alike regularly saying that their katana isn’t fully sharpened. Have you ever noticed that the blade edge of a katana near the habaki (blade collar) is not sharpened?

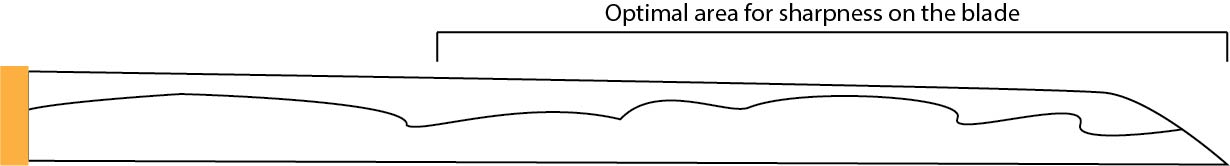

Most people are not aware that about a quarter of the blade toward the guard is left unsharpened. The blade edge increases in sharpness about a third of the way from the guard to the tip. Defect or design feature?

The function of the blade left unsharpened is to prevent stress risers (or stress raisers) from forming in the steel. A stress riser a place in a piece of steel where the concentration of pressure (or stress) is greater than the surrounding area. A stress riser usually forms where sharp edges are present. The more edge you have the greater potential for stress risers. To decrease the odds of preventing stress risers during a bad cut or just normal use, the blade makers over time used this technique.

Therefore, you don’t want your katana sharpened fully down the blade because technique is everything when cutting. As you move away from the "sweet spot" in the optimal range of where the sharpness needs to be and where you should be cutting with the blade, the blade shape becomes more convex the closer you get to the habaki.

Bad cutting technique leads to incorrect placement of stress on the blade which could lead to a broken blade. Obviously, there are other reasons blades break (bad temper, flaws in the steel, etc.) But when you get your katana you should take the time to appreciate this subtle yet important sharpening technique to improve the longevity of your blade.